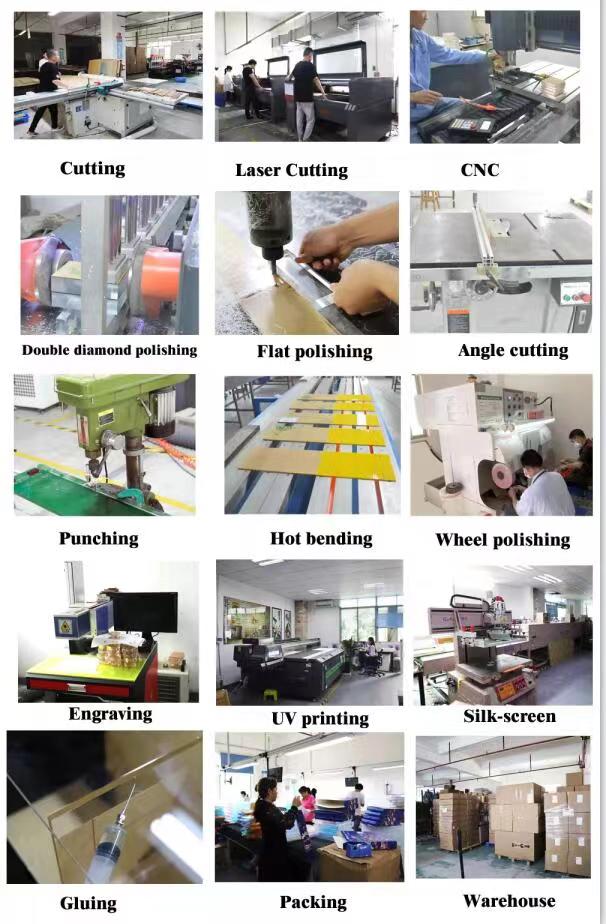

The latest process for making acryic display stand

With the continuous progress of social economy, acrylic materials have been widely used in our life. Acrylic, also known as plexiglass, is a plastic polymer material developed earlier, with chemical stability, weather resistance and better transparency, easy to process, easy to dye, beautiful appearance.

- Cutting: according to the size requirements of the acrylic products, the sawing machine is used to cut, so as not to cause waste of materials.

- Engraving: after cutting according to the requirements of the shape of the acrylic products, engraving a variety of patterns, words or logo, etc.

- Drilling: acrylic can be directly used bench drilling machine, in accordance with the requirements of the processing drawings directly on the drilling machine fixed, direct positioning drilling is good.

- Trimming: after cutting or engraving, the edge of acrylic sheet is rough, so acrylic trimming should continue to use vertical single-axis woodworking engraving and milling machine to solve.

- Polishing: after opening, engraving, drilling, the edge is still rough, easy to scratch the hand, therefore, the need to use polishing process, can choose different polishing methods according to the different products. Polishing is also divided into flame polishing machine, cloth polishing machine and diamond polishing machine.

- Tear paper: acrylic board after factory will have a layer of protection paper, in hot bending and screen printing must be removed before the sticker pasted in acrylic board.

- Hot bending: acrylic can be changed into different shapes through hot bending, in hot bending is also divided into overall hot bending and local hot bending.

- Screen printing: If the users need to display the brand logo or propaganda, will use UV printer for processing.

- Bonding: bonding process depends on manual processing, the bonding process should be strictly controlled, so the experience of the staff is very important, not only according to the position of the drawing design to bond, but also can not stick crooked, foaming, bonding is not strong, after strict control of the product is allowed to ship. Common bonding processes include butt, facade bonding, 45° bevel bonding and surface bonding.

- Assembly: Assembling parts together to make a complete product.

- Packaging: after the assembly, the final quality test of the whole product, must be determined qualified, and then arrange packing and shipment.